Lobachevskii Journal of Mathematics

Vol. 13, 2003, 25 – 38

©R.F. Kadyrov, E. Laitinen, and A.V. Lapin

R.F. Kadyrov, E. Laitinen, and A.V. Lapin

USING EXPLICIT SCHEMES FOR CONTROL PROBLEMS IN

CONTINUOUS CASTING PROCESS

|

________________

2000 Mathematical Subject Classification. Primary. 65M60,49J20.

Key words and phrases. Stefan problem, continuous casting process, optimization

problem, finite element method, explicit scheme.

This work is supported by RFBR, project N 01-01-00068..

|

ABSTRACT. In this article, we solve an optimal control problem of the

cooling process in the steel continuous casting, which mathematical

formulation is a coefficient identification problem for Stefan problem with

prescribed convection. To minimize a cost function we use a gradient method,

state and adjoint state problem being approximated by explicit mesh schemes

with variable time steps. Presented numerical results show an advantage in

calculations time of this approach in comparison with using implicit mesh

schemes.

1. Introduction

A continuous casting process can be described by the Stefan problem with

prescribed convection [1, 2]. The existence of a unique solution for this problem is

proved in [3]. For numerical solving of this problem the fully implicit schemes or the

implicit schemes with characteristics approximation of heat transfer operator are

traditionally used (cf., e.g., [4, 5, 6] and bibliographies therein). These schemes are

unconditionally stable, but SOR-types methods which are commonly used for

its numerical solving have a slow convergence rate. More sophisticated

methods are based on the domain decomposition [7, 8] and/or multigrid

procedures [9]. Nevertheless, when using any of these approaches we get a

system of nonlinear equations which have to be solved again by using SOR

method.

On the other hand, a computational complexity of one step of an explicit scheme

is the same as for one SOR-iteration. It is well known, that the explicit schemes

with constant steps in time are only conditionally stable. This essentially restricts

the field of their application in solving the applied problems. At the same time, in

[10, 11, 12] the effective algorithms for solving both linear, and nonlinear

non-stationary problems have been suggested, these algorithms being based on the

explicit schemes with variable steps.

In this paper, the results of using the explicit schemes with variable steps for

solving a 3D dynamic control of the secondary cooling process in continuous casting

problem are presented.

The rest of the article is organized as follows. In the second section the

boundary-value problem is posed in two formulations: a temperature formulation

(unknown is the temperature field) and enthalpy formulation (unknown is enthalpy

function). To solve the problem in temperature formulation we use an implicit

scheme with FEM approximation in space variables, while for the problem in the

enthalpy formulation an explicit Euler method with cycle of variable steps with the

same FEM approximation in space is used. In the third section of the paper a

cooling optimization problem for the continuous casting process is described.

We construct a method for solving this problem which is based on the

explicit approximations with variable steps of both direct and adjoint state

problems. In the last section some numerical results are presented. The main

conclusion of these numerical results is: the calculated control functions and

temperature fields are very close for both methods, while the computational

complexity of the explicit scheme is less than for the implicit one. This fact is

very important for our applied problem which must be solved in real-time

regime.

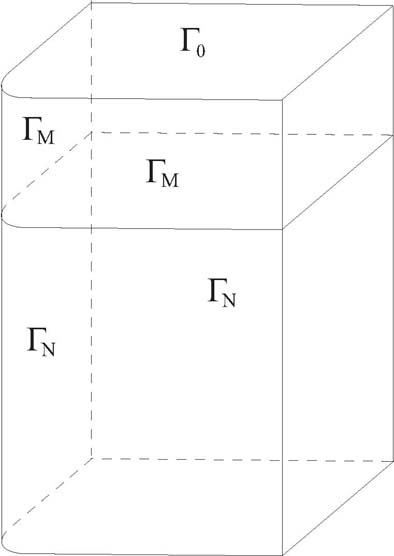

2. Boundary-value problem formulation

Let Ω¯ ∈ R2 be the rectangular

domain 0,Lx ×0,Ly with round

left-down corner of radius R ≥ 0,

Ω¯= Ω ∪ ∂Ω. Let

V = Ω ×0,Lz be the 3D domain

with boundary Γ = ∂V

which consists of the following parts:

Γ0 = Ω¯ ×0 ,

ΓN = x,y ∈ ∂Ω : x = 0 ∨ y = 0 ×LM,Lz ∪ Ω ×Lz ,

ΓS = x,y ∈ ∂Ω : x≠0 ∧ y≠0 ×0,Lz ,

ΓM = x,y ∈ ∂Ω : x = 0 ∨ y = 0 ×0,LM ,

where 0 ≤ LM < Lz.

In our applied problem domain V

represents a metallic bar (or melt), Ω

is the quarter of z-cross section of a slab,

Lz is the length

of a slab and LM

is the length of primary cooling zone.

We find the temperature field T = T(x,y,z,t)

for (x,y,z) ∈Ω¯

and t ∈ (0,Tf]

( T f is

the time of casting process ending).

We define the enthalpy function H(T)

and the Kirchoff’s temperature K(T)

by

H T = ρ ∫

0T c ξdξ + L 1 − f

s T,K T = ∫

0T k ξdξ ,

where ρ,

c(T),

k(T) and

L

are density, heat capacity, thermal conductivity and latent heat,

fs T is the solid fraction

at temperature T,

such that

fs T = 1,T > Ts,

0,T < Tl.

Here Ts is the

solidification and Tl

is the melting temperature. On Figures 2, 3 the graphs of enthalpy

function and Kirchhoff’s temperature for steel are presented. Note

that because of the monotonicity and continuity of enthalpy function

H = H(T), we can define the

inverse function T = T(H).

The continuous casting process can be modelled by the following boundary-value

problem:

|

∂H(T)

∂t + v∂H(T)

∂z − ΔK T = 0inV ×0,Tf ,

T = T0onΓ0 ×0,Tf ,

∂K T

∂n + h T − Tw + σɛ T4 − T

ext4 = 0

onΓN ×0,Tf ,

∂K T

∂n = QonΓM ×0,Tf ,

T x,y,z, 0 = T0inV.

| (1) |

Here n is the unit vector

of outward normal to ∂V ,

σ > 0 is the Stefan-Bollzmann

constant, ɛ > 0 is the

emissivity, v > 0 is the

casting speed, h = h x,y,z,t

and Q = Q x,y,z are known

cooling functions, Tw = Tw x,y,z

and Text = Text x,y,z

are known temperatures of cooling liquid and environment,

T f is the

time of casting process ending.

Besides of the temperature-enthalpy formulation (1) we use the following

enthalpy formulation:

|

∂H

∂t + v∂H

∂z − ΔK H = 0inV ×0,Tf ,

H = H(T0)onΓ0 ×0,Tf ,

∂K H

∂n + h T H − Tw + σɛ T4 H − T

ext4 = 0

inΓN ×0,Tf ,

∂K H

∂n = QinΓM ×0,Tf ,

H x,y,z, 0 = H0onV.

| (2) |

Unknown function in (2) is the enthalpy function

H(⋅), by

K(H) we mean

here K(T(H)).

3. Mesh problem and its solving

Let for some ɛ > 0

we know τ = τ ɛ,

such that the following condition holds:

∂H

∂t + v∂H

∂z = H −H˜

τ + ω t, with ∥ω t∥≤ ɛ,∀t : 0 ≤ t < t + τ ≤ Tf,

where H˜ = H x,y,z − vτ,t − τ. In fact, this

means that for this τ the

local ɛ-approximation

of the term ∂H∕∂t + v∂H∕∂z

in a norm ∥⋅∥

is achieved.

The weak formulation of the semi-discrete scheme to problem (1) for a fixed time

level can be written as follows:

|

findH ∈ H1(V ),H ∣

Γ0 = H(T0) :

1

τ ∫

V H T −H˜τηdx + ∫

V ∇K T ⋅∇ηdx+

+ ∫

ΓNh T − Tw + σɛ T4 − T

ext4 ηdx = 0,

∀η ∈ V 0 = v ∈ H1 V : η

Γ0 = 0 .

| (3) |

Here H1 V

is the usual Sobolev space.

Let Ω

be partitioned into a set of quadrilateral finite elements, this triangulation

being topologically equivalent to rectangular one. The triangulation of

Ω and partitioning of

[0, Lz] form the triangulation

of 3D domain V

into a set of prismatic 3D finite elements. Now we can write

the finite element (FEM) discretization of problem (3). Let

V h

be a finite element approximation of the space

H1 (V ), based on the polylinear

elements. Further wh stands

for a V h-approximation

of function w (for a

continuous function w

wh is its

V h -interpolant).

Let

V hT0

= vh ∈ V h V : vh = T0h on Γ0 ,

V h0 = v

h ∈ V h V : vh = 0 on Γ0 .

Approximation of problem (3) by finite element method is defined as

|

1

τ ∫

V Hh Th −H˜hηdx + ∫

V ∇Kh Th ⋅∇ηdx+

+ ∫

ΓNh Th − Tw,h + σɛ T4

h −Text4

h ηdΓN = 0,

∀η ∈ V h0.

| (4) |

Discrete problem (4) is equivalent to the system of nonlinear algebraic equations

(hereafter we use the same notations for continuous and mesh functions):

|

H T −H˜

τ + AK T + B h T − Tw + B T4 − T

ext4 = 0.

| (5) |

Here: A

is the discrete Laplas operator, in current FEM realization

A is the 11-diagonal

matrix; B,B h

are the diagonal matrices with sparse main diagonal.

In enthalpy formulation problem (5) becomes

|

H −H˜

τ + AK H + B h T H − Tw +

+B T H4 − T

ext4 = 0.

| (6) |

Below we consider the problem in enthalpy statement (6). Let

f H = AK H + B h T H − Tw + B T H4 − T

ext4 .

Then an explicit Euler method can be written as

|

Hk+1 = Hk − τk+1f Hk ,H0 = H T0 ,k = 0, 1, 2,…

| (7) |

Here τk are the time steps,

Hk = H t = ∑

i=1kτi is the numerical solution

at the time level t.

The Frechet derivative of the mapping

f H is

given by

J(H) = A ∘ K′(H) + B h ∘ T′(H) + 4B ∘T3(H)T′(H) .

Let λ,ξ is the eigen

pair of operator J,

then

K′ + A−1B hT′ + 4A−1BT3T′ξ = λA−1ξ.

Hereafter we omit the argument H

of functions T,

T ′ and

K′ .

Executing some technical estimates we get the following inequalities:

K′ξ,ξ + A−1B hT′ξ,ξ + 4 A−1BT3T′ξ ≤

≤ LKHλ

maxA A−1ξ,ξ + 4 A−1BT3T′ξ,BT3T′ξ A−1ξ,ξ1∕2+

+ A−1B HT′ξ,B HT′ξ1∕2 A−1ξ,ξ1∕2 ≤

≤ LKHλ

maxA + cond A1∕2L

T H B h +

+4 cond A1∕2L

T HL

T3H A−1ξ,ξ.

Now, maximum eigenvalue of operator

J can

be estimated by

λmax ≤ LKHλ

maxA + cond A1∕2L

T H B h

+4 cond A1∕2L

T HL

T3H.

Here:

- λmaxA

is the maximum eigenvalue of the operator A;

- cond A = λmaxA

λminA

is the condition number of operator A;

- LKH = sup

H∈[H(0),H(Ts)] K′H;

- LT H = sup

H∈[H(0),H(Ts)] T′H;

- LT3H = sup

H∈[H(0),H(Ts)] T3 H.

Let τk = τ

0,

then we have the explicit Euler method with constant step.

Approximation condition in this case is defined by following inequality:

τ0 ≤ τ. Stability condition can

be written as τ0 ≤ cou, where

Courant number cou = 2∕λmax. As it is

known, for large value of λmax

the last condition is too restrictive and too many steps in time can be necessary

when using an explicit scheme.

Let τk

k=1N be a cycle of

time steps in (7), N

be the length of the cycle. The total step of the cycle is

lN (τmax) = ∑

k=1Nτk,

where τmax

is the maximum step of the cycle. The approximation condition of this scheme can

be written as

The relaxed stability condition of this so-called super-time-stepping scheme is

|

∏

k=1N(1 − τ

kλ) < 1∀λ : (λmin ≤ λ ≤ λmax),

| (9) |

where λmin

and λmax

is the minimum and maximum eigenvalues of the operator

J.

To obtain an optimal scheme, a maximum superstep size must be found as maximum

lN (τ(ɛ))

when (8) and (9) hold. An optimal cycle is found by using the

optimal properties of Chebyshev polinomials in [10] for the cases

N = 2p and

N = 2p3q. The

construction of this scheme is based on the using the following parameters:

τmax ≤ τ(ɛ) – the maximum

step of the cycle, cou

– Courant number of the operator.

This scheme is described for the operators with real spectrum. In our problem

operator J

is symmetrizable, thus it has only real spectrum.

In our case we have parameter τf ≫ τ(ɛ)

and we must calculate solution for every time

t = kτf,k = 0, 1, 2,…

It means that we need the time steps cycle such that

lN ≈ τf. Obviously, function

g(x) = ∣τf − lN(x)∣, 0 < x ≤ τ(ɛ) is unimodal for every

fixed N, and it means

that for all fixed ξ > 0

we can easily find τ : g(τ) ≤ ξ.

Values N = 2p

and τ

were defined experimentally. Using explicit scheme with cyclic set of

steps we get some advantage in computing complexity in comparison

with the scheme with a constant step, but it has not a theoretical

N-order advantage, because

we have condition lN ≈ τf.

In the next section we also compare explicit schemes with variable steps

with standard implicit method (see Table 1). The solution of nonlinear

system arising in the implicit scheme was made by Gauss-Seidel method with

preliminary Newton linearization. In column ”Number of iterations” of Table 1 we

present: for the implicit scheme – average number of the iterations required

for the solving of corresponding system of the nonlinear equations at one

time level, for the explicit scheme – number of steps in a cycle. In column

”Time of iteration” the average time of one iteration in milliseconds is

recorded.

4. Optimization problem

The secondary cooling region is divided into

M

cooling zones, in every one the heat transfer coefficient

hk ,k = 1,M¯ have to

be controlled. In optimal control method our aim is to minimize a goal function which

is constructed by means of metallurgical cooling criteria. By these criteria we have two

observation lines on the slab surface (along the corner and center lines of slab surface):

l1 = ((x,y,z) ∈ Γ : x = y = R(1 − 1∕2),z ∈ [LM,Lz]),

l2 = ((x,y,z) ∈ Γ : x = Lx,y = 0,z ∈ [LM,Lz]) and given target

temperatures {tktar,k = 1,M¯¯}

for starting point of each cooling zone along this lines. Let

T tar(x),x ∈ l = l

1 ∪ l2 is the linear

interpolation of {tktar}.

Thus, the goal-function can be defined as

I(T) = 1

2 ∫

l(Ttar − T)2dx.

Let J(T) is the mesh

approximation of I(T),

vector J′(T) is

the derivative of the goal-function. We can formulate the optimal control problem in

the following way:

Find h∗ ∈ U

such that:

|

J(h∗) = min

h∈UJ(h),

| (10) |

where U = {u = (u1,u2,…,uM) : hmin ≤ ui ≤ hmax∀i = 1,M¯}

is the set of constraints for control variables and

T = T(h) is

defined via solution of mesh scheme (6) with the set of variable time steps. Thus, we

have a nonlinear function minimization problem with constraints. To solve problem

(10) we use a gradient method.

To calculate the gradient of the goal-function we construct the adjoint state

problem by using the Lagrange function

L = J(TN)+

+ ∑

k=1N−1Hk+1 − Hk

τk + AK(Tk) + B(h)(Tk − T

w) + B (Tk)4 − T

ext4 ,λk+1.

Here we use the inner product (⋅,⋅)

in the finite dimensional space of vectors. Variation gives

Ly′v = J′(TN) + ∑

k=1N−1vk+1 − vk

τk + A K′(Tk)(Tk)

H′vk ,λk+1+

+ ∑

k=1N−1B(h)(Tk)

H′vk + 4B(Tk)3(Tk)

H′vk,λk+1 = 0.

Obviously,

∑

k=1N−1vk+1 − vk

τk λk+1 = ∑

k=1N−1vk λk

τk −λk+1

τk+1 + vNλN

τN ,λ1 = 0

From here we derive the following system of the linear algebraic equations, which is

the mesh adjoint state problem:

|

λN

τN + J′(TN)(TN)

H′ = 0

λk

τk −λk+1

τk+1 + (Tk)

H′K′(Tk)A∗λk+1 + (Tk)

H′B∗(h)λk+1+

+ 4(Tk)

H′(Tk)3B∗λk+1 = 0,k = N − 1,…, 1.

| (11) |

As it is shown in [10] scheme (11) is stable and stable to round-off errors. Now the

descend direction is defined by

(J′(h))

j = (B(hj)(T − Tw),λ1),

where: hj = 0,…, 0, 1,…, 1︷ ikj

, 0,…, 0T ,j = 1,M¯;

ik j - all mesh points in

the j-th cooling zone.

Vector −J′(h) is the descent

direction. The projection p = (p1,p2,…,pM)

of the vector −J′(h) to

constrains set U

can be calculated as

pi = 0,(hi = hmin ∧ Jj′ > 0) ∨ (h

i = hmax ∧ Jj′ < 0),

−Ji′,otherwize.

Then we consider the one-dimensional minimization problem:

|

ρopt = arg min 0≤ρ≤ρmaxJ(h + ρp),

| (12) |

where maximum descent step ρmax

can be found from: start point h,

current descent direction p

and constraints set U.

In this work we solve (12) by the Brent algorithm of one-dimension minimization

and by the following algorithm:

Step 1.

Let h(ρ) = h + pρ

ρ0 = ρmax

2d ,

where d > 0

is the arbitrary parameter of algorithm

If J(h(ρ0)) > J(h(0))

Then ρopt = 0

End

i = 1

GoTo Step 2

Step 2.

ρopt = ρi−1

ρi = 2ρi−1

If ρi > ρmax

or J(h(ρi)) > J(h(ρi−1))

End

i = i + 1

GoTo Step 2.

The solutions of (10) using both one-dimensional minimization algorithms are the

same, while the second algorithm is much simpler than Brent algorithm.

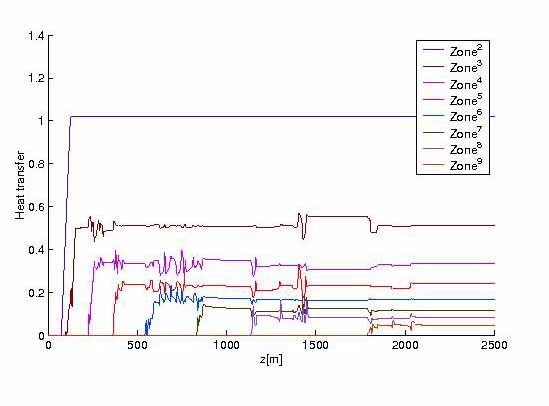

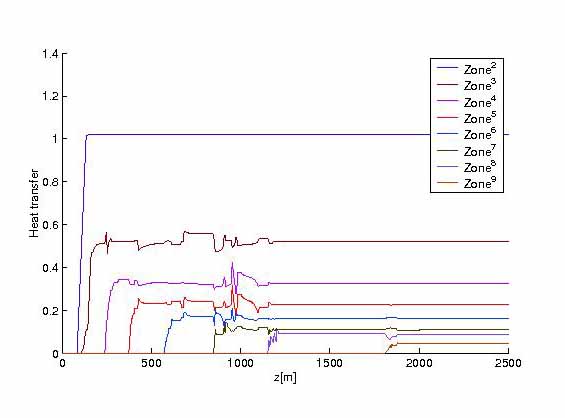

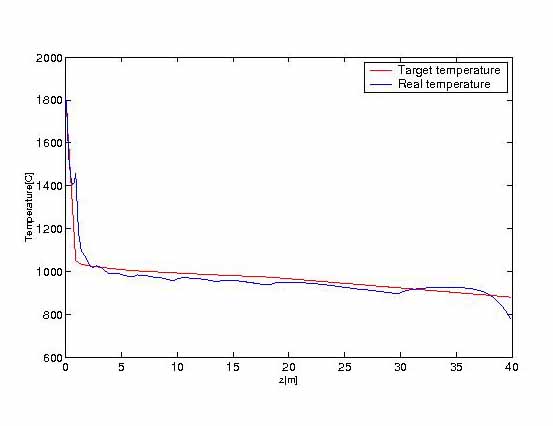

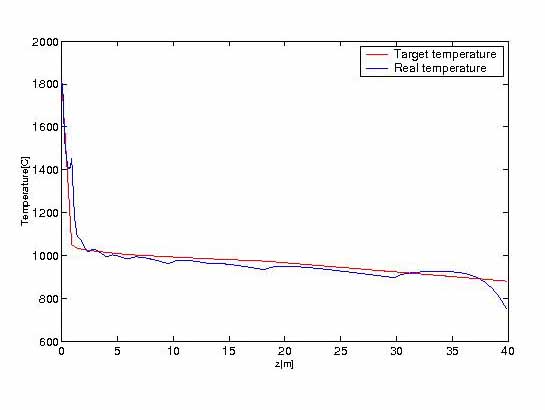

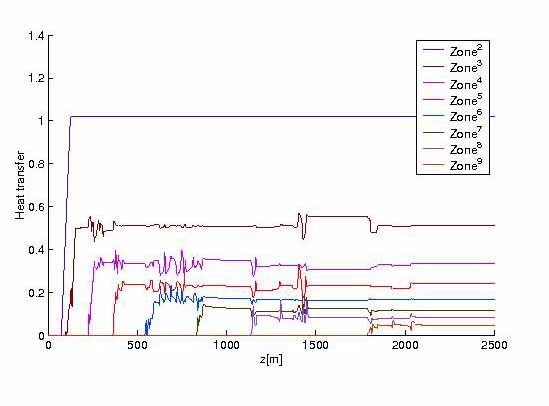

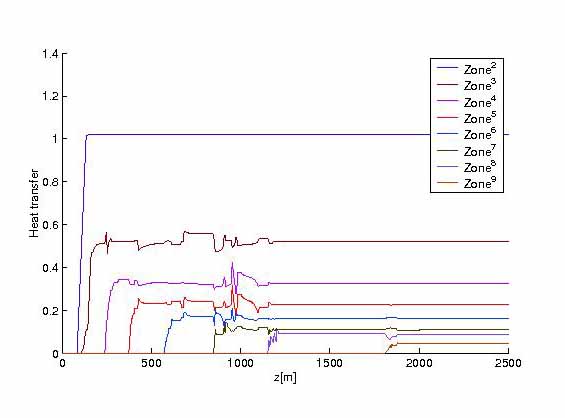

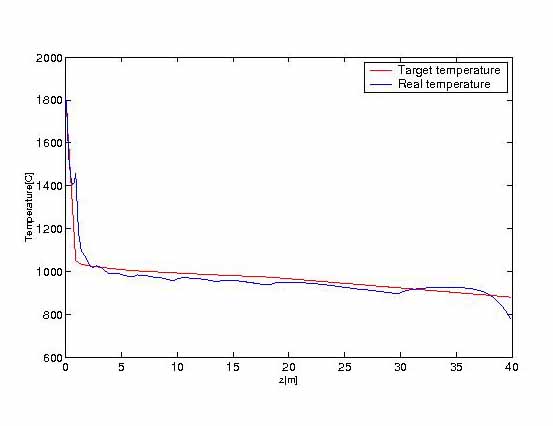

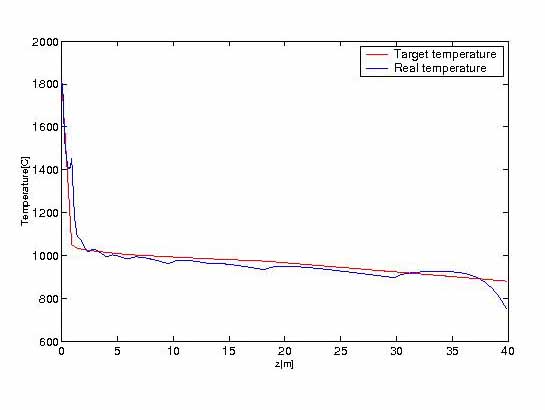

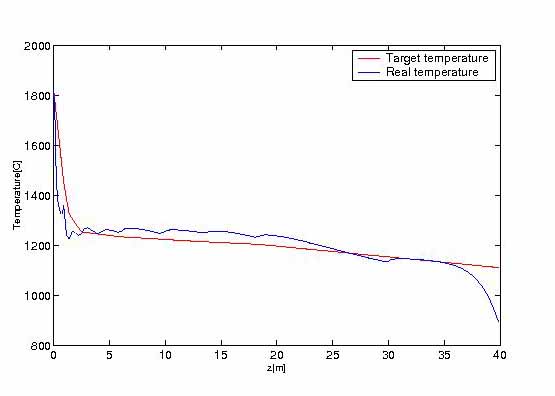

The results of numerical experiments (optimal control and temperature fields

calculated by using both explicit and implicit schemes) are presented on Figures 4 –

9.

5. Numerical results

Direct solution.

|

|

|

|

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| | |

| | |

| |

| |

| |

| | Method | | | Time of one |

| iteration |

| (ms) |

| |

|

|

| Mesh: 11x17x221 |

| Tf = 1000 |

| |

| Explicit scheme | 8 | 116 |

|

| Implicit scheme | 24 | 256 |

|

|

| Explicit scheme | 8 | 56 |

|

| Implicit scheme | 19 | 107 |

|

|

| Explicit scheme | 4 | 28 |

|

| Implicit scheme | 14 | 73 |

|

| |

TABLE 1. Number of iterations and time of calculation for solution of the state

problem.

Optimization.

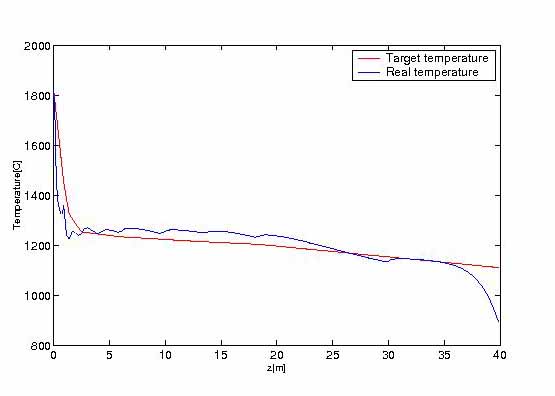

FIGURE 4.

FIGURE 4. Optimal cooling control results by implicit scheme

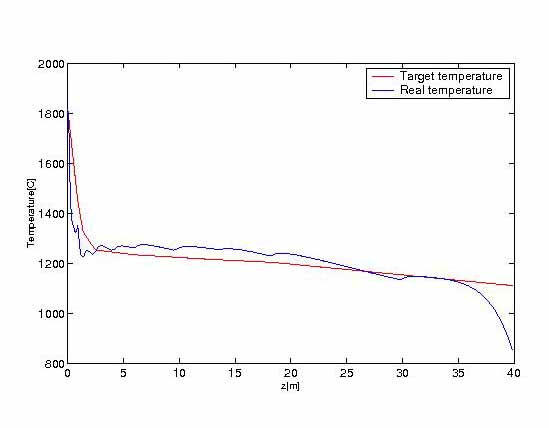

FIGURE 5.

FIGURE 5. Optimal cooling control results by explicit scheme

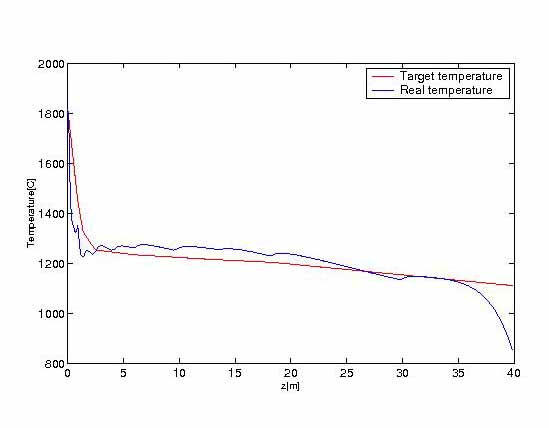

Optimal and target temperatures

FIGURE 6.

FIGURE 6. Temperature by implicit scheme along corner line

FIGURE 7.

FIGURE 7. Temperature by explicit scheme along corner line

FIGURE 8.

FIGURE 8. Temperature by implicit scheme along center line

FIGURE 9.

FIGURE 9. Temperature by explicit scheme along center line

References

[1] Laitinen E., Neittaanma¨ki

P. On numerical simulation of the continuous casting problem //J. Eng. Math. – 1987.

– V. 22. – P. 335–354.

[2] Louhenkilpi S., Laitinen E., Nieminen R. Real time simulation of heat transfer in

continuous casting // Metall. Trans. B. – 1993. – V. 24B. – P. 685–693.

[3] Rodrigues J. F., Yi F. On a two-phase continuous casting Stefan problem with nonlinear

flux // Euro J. App. Math. – 1990. – V. 1. – P. 259–278.

[4] Chen Z., Jiang L. Approximation of a two phase continuous casting problem // J. Part.

Diff. Equations. – 1998. – V. 11. – P. 59–72.

[5] Laitinen E., Lapin A. Implicit approximation and iterative solution for the continuous

casting problem // Preprint, July, 1999, Dep. of Math. Sci., University of Oulu. – 1999.

– 17 p.

[6] Laitinen E., Lapin A., Pieska¨

J. Mesh approximation and iterative solution of the

continuous casting problem // in: ENUMATH 99. Ed. by P.

Neittaanma¨ki,

T. Tiihonean and P. Tarvainen. World Scientific, Singapore. – 2000. – P. 601–617.

[7] Laitinen E., Saranen J., Pieska¨

J., Lapin A. Comparison of domain decomposition methods for solving continuous

casting problem // in: Domain Decomposition Methods DDM-13. Ed. by N. Debit, M.

Garbey, R. Hoppe, J. Periaux, D. Keyes, Y. Kuznetsov. CIMNE, Barselona. – 2002. –

P. 411–418.

[8] Laitinen E., Lapin A., Pieska¨

J. Asinchronous domain decomposition methods for solving continuous casting problem

// J. of Comp. and Appl. Math. – 2003. – V. 154. – P. 393–413.

[9] Dautov R.Z., Ignatieva M.A. Multigrid solution of a two-phase Stefan problem with

prescribed convection // Proceedings of Russian-Finnish Workshop: Numerical methods

for continuous casting and related problems, V. 9. – Kazan, DAS Publisher, 2001, –

pp. 3-11.

[10] Lebedev V.I. Functional analysis and calculus mathematics. – M.: Science, 2000. – 290

P.

[11] Lebedev V.I. Explicit difference schemes for solving stiff systems of ODEs and PDEs

with complex spectrum//Russ. J. Numer. Anal. Math. Modelling. – 1998. – V. 13. – No 2.

– P. 107–116.

[12] Lebedev V.I. Explicid difference schemes for solving stiff schemes with complex or

partitioned spectrum//JNM and MP. – 2000. – V. 40. – No 12. – P. 1801–1812.

KAZAN STATE UNIVERSITY, RUSSIA

UNIVERSITY OF OULU,FINLAND

KAZAN STATE UNIVERSITY, RUSSIA

E-mail address: alapin@ksu.ru

Received October 15, 2003

FIGURE 8. Temperature by implicit scheme along center line

FIGURE 8. Temperature by implicit scheme along center line  FIGURE 9. Temperature by explicit scheme along center line

FIGURE 9. Temperature by explicit scheme along center line